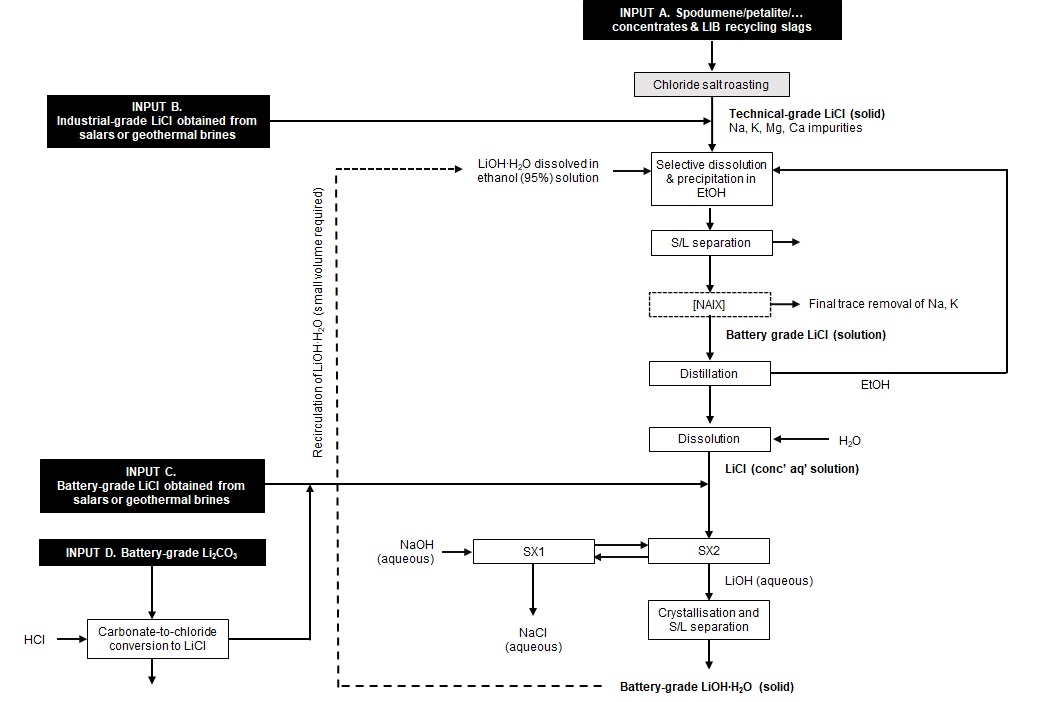

In May 2020, SOLVOMET filed the patent application “Method for producing battery grade lithium hydroxide monohydrate” (priority date: 2020-05-13). The patent application (WO2021228936A1, Prof. Koen Binnemans) became public in November 2021. The first part of the patented flowsheet, involving a one-step (solvometallurgical) process to purify technical-grade lithium chloride into battery-grade quality, was disclosed in June 2022 through a first paper in Journal of Sustainable Metallurgy. The second part of the patented flowsheet, which allows to obtain the coveted battery-grade lithium hydroxide monohydrate (LiOH·H2O) through a unique double solvent extraction process, is now disclosed through a new paper in Journal of Sustainable Metallurgy (https://rdcu.be/c03Sp) .

Why lithium hydroxide monohydrate?

The importance of lithium hydroxide, in the form of its monohydrate, is increasing rapidly, mainly because it can be used as a starting compound for nickel-rich NMC cathode materials for high-performance Li-ion batteries. A process for direct conversion of lithium chloride into lithium hydroxide, bypassing the lithium carbonate intermediate, would be advantageous to reduce the number of processing steps for obtaining lithium hydroxide. However, such process implies the purification of technical-grade lithium chloride, through the removal of common impurities such as sodium, potassium, calcium and magnesium.

A unique double SX process

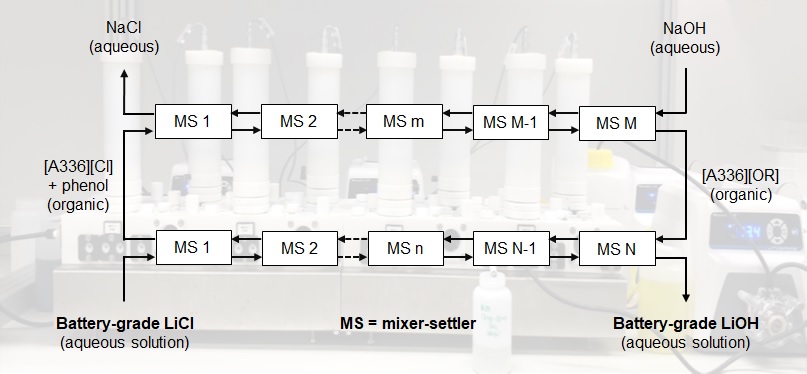

In this new Journal of Sustainable Metallurgy paper, SOLVOMET KU Leuven discloses a hydrometallurgical process for the conversion of an aqueous solution of lithium chloride into an aqueous solution of lithium hydroxide via a chloride/hydroxide anion exchange reaction by solvent extraction. The organic phase comprises a quaternary ammonium chloride and a hydrophobic phenol in a diluent.

The best results were observed for a mixture of the quaternary ammonium chloride Aliquat 336 and 2,6-di-tert-butylphenol (1:1 molar ratio) in the aliphatic diluent Shellsol D70. The solvent extraction process involves two steps. In the first step, the organic phase is contacted with an aqueous sodium hydroxide solution. The phenol is deprotonated, and a chloride ion is simultaneously transferred to the aqueous phase, leading to in situ formation of a quaternary ammonium phenolate in the organic phase.

The organic phase, comprising the quaternary ammonium phenolate, is contacted in the second step with an aqueous lithium chloride solution. This contact converts the phenolate into the corresponding phenol by protonation with water extracted to the organic phase, followed by a transfer of hydroxide ions to the aqueous phase and chloride ions to the organic phase.

As a result, the aqueous lithium chloride solution is transformed into a lithium hydroxide solution. The process has been demonstrated in continuous counter-current mode in mixer–settlers. Solid battery-grade lithium hydroxide monohydrate was obtained from the aqueous solution by crystallization or by antisolvent precipitation with isopropanol.

The process consumes no chemicals other than sodium hydroxide. No waste is generated, with the exception of an aqueous sodium chloride solution.

Patent application “Method for producing battery grade lithium hydroxide monohydrate”

The results presented in the paper constitute the second part of a broader flowsheet (see Figure 1) to convert technical-grade LiCl into battery-grade LiOH·H2O (cf. patent application WO2021228936A1: Method for producing battery grade lithium hydroxide monohydrate: Priority 2020-05-13, Filed 2021-05-12, Published 2021-11-18: https://patents.google.com/patent/WO2021228936A1/en). Companies that are interested in this patent application can contact Dr. Peter Tom Jones, Industrial Research Fund Valorisation Manager for the SOLVOMET KU Leuven Research Group, through his LinkedIn profile.

Full reference of two JSM papers

Paper 1: Dženita Avdibegović, Viet Tu Nguyen, Koen Binnemans “One‑Step Solvometallurgical Process for Purification of Lithium Chloride to Battery Grade”, Journal of Sustainable Metallurgy, 2022, 8, 893–899. doi.org/10.1007/s40831-022-00540-w (Open Access paper).

Paper 2: Viet Tu Nguyen, Clio Deferm, Ward Caytan, Sofía Riaño, Peter Tom Jones, Koen Binnemans, “Conversion of Lithium Chloride into Lithium Hydroxide by Solvent Extraction”, Journal of Sustainable Metallurgy, https://doi.org/10.1007/s40831-022-00629-2 (Open Access paper). Download pdf here: https://rdcu.be/c03Sp

Acknowledgements

The research leading to these results has received funding from the European Research Council (ERC) under the European Union's Horizon 2020 Research and Innovation Programme: Grant Agreement 963281 (PoC grant SOLVOLi: https://cordis.europa.eu/project/id/963281), and from KU Leuven (project C3/20/066). This publication reflects only the author's view, exempting the Community from any liability.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant