On November 15, the key outcomes of the EU NEMO project were presented at the NEMO Satellite Event in the framework of the 7th EU Raw Materials week in Brussels. All presentations are now available. NEMO (“Near-zero-waste recycling of low-grade sulphidic mining waste for critical-metal, mineral and construction raw-material production in a circular economy”) is a EU H2020 Innovation Action project. Since 2018 it has developed and upscaled different technologies for the production of metals (Ni, Co, Cu, Zn, REE, Mn), minerals and construction raw materials from sulphidic mining waste. In this way, the project aims to transform the EU extractive waste problem into a business opportunity.

NEMO scope and objectives

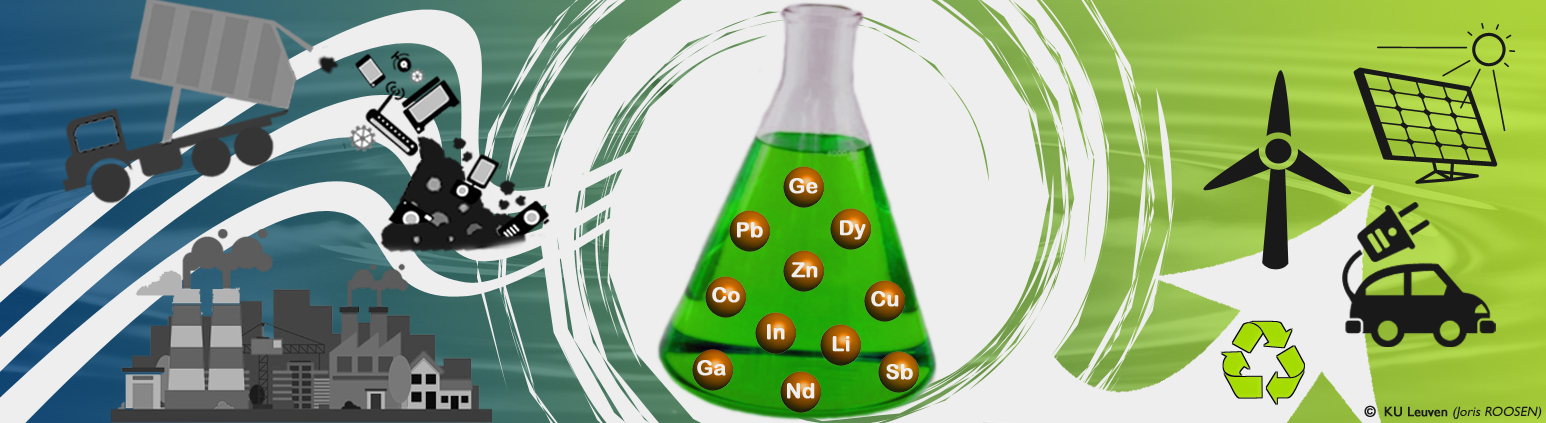

Nowadays, sulphidic mining waste from copper, lead, zinc and nickel production represents Europe’s largest volume of extractive waste. When poorly managed, this waste may cause major environmental problems, such as acid mine drainage. At the same time, these materials still contain many valuable & critical metals that are highly needed for the green transition.

Therefore, the NEMO project proposes technologically sound methods to valorise this waste stream at 3 mining sites in the EU. The NEMO technology enables (1) the recovery of valuable & critical metals, (2) the safe concentration of hazardous elements, (3) the removal of sulphur as sulphate salts and (4) the use of the cleaned residual mineral fraction for construction applications (cement and concrete products).

NEMO’s near-zero-waste technologies provide the EU with direct and indirect long-term advantages. Mining waste is used as a secondary resource for raw materials including base metals: Cu, Zn, Ni; critical metals: Co, REE; supplementary cementitious materials and aggregates. CO2 emissions are saved as primary metal production and Ordinary Portland Cement production are avoided. Acid-mine drainage is eliminated and other environmental risks are reduced. Furthermore, jobs are created. Taken as a whole, the benefits of the NEMO project support increasing the well-being of the citizens and the sustainable sourcing of raw materials for the EU.

Curious about the results?

An overview of the main NEMO results can be found here:

- Introductory presentation – Anders Sand, Boliden

- Innovative hydrometallurgy for sustainable valorisation of mining waste – Anne-Gwénaëlle Guezennec – BRGM (French Geological Survey)

- Demonstration of the use of mine tailings in cement and concrete: From bin to big-bag and beyond – Arne Peys, Vito and Thomas Lapauw, Resourcefull

- Sustainability Assessment in NEMO – Andrea Di Maria, KU Leuven

- Stakeholder Engagement – Alberto Vázquez Ruiz, Catapa

Acknowledgements

The NEMO project has received funding from the European Union's EU Framework Programme for Research and Innovation Horizon 2020 under Grant Agreement. More info at https://h2020-nemo.eu/

Authors

Dr. Lieven Machiels & Dr. Peter Tom Jones (SIM² KU Leuven)

Pictures

.jpg)

Innovative hydrometallurgy for sustainable valorisation of mining waste – Anne-Gwénaëlle Guezennec – BRGM (French Geological Survey)

Introductory presentation – Anders Sand, Boliden

BRGM's pond bioleaching model

NEMO boot, 15-11-2022, with Mohammad Khoshkhoo (Boliden) and Thomas Abo Atia (KU Leuven)

NEMO concrete floor comprising sulphidic tailings – tests at VITO, Mol – with Resourcefull and Jacobs Beton

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant