SOLVOMET/SIM² researchers have successfully demonstrated a hydrometallurgical flowsheet for upgrading ferronickel (Class-II nickel) into battery grade nickel (Class-I nickel) in a mini-pilot SX facility.

The increasing electrification of the transportation sector and the need for fast energy storage in the electric grid has amplified the criticality of battery metals such as nickel and cobalt. To reduce Europe’s dependency on third countries for the mining and refining of battery metals, a domestic European materials value chain has to be created.

Hence, KU Leuven researchers from SOLVOMET/SIM² have developed a hydrometallurgical flowsheet for upgrading ferronickel (Class-II nickel) into battery grade nickel (Class-I nickel), while recovering as much as possible of the used reagents. For the first time, the continuous counter-current solvent extraction process has been carried out successfully at SOLVOMET’s mini-pilot SX facilities.

Circular hydrometallurgy

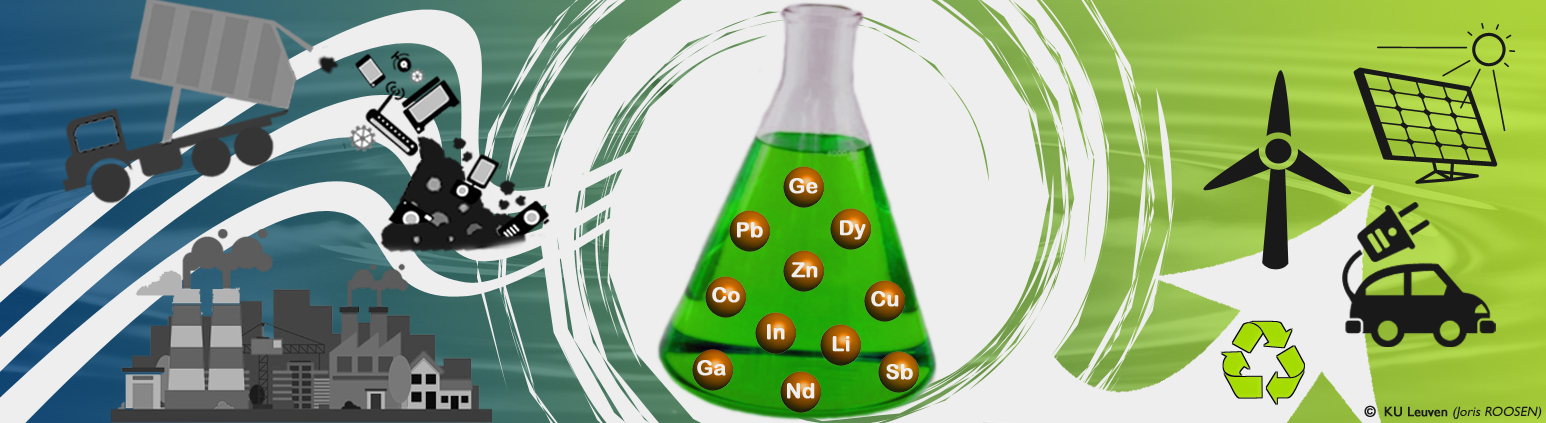

Circular hydrometallurgy is the area of hydrometallurgy that focuses on the design of energy-efficient flowsheets or unit processes that consume a minimal amount of reagents and produce virtually no waste.1 It entails a different way of thinking about how hydrometallurgy is practiced, both for primary mining and recycling processes. Circularity refers to the regeneration and reuse of all the reagents in a process.

In ENICON processes, this is reflected by a strong focus on the reuse of reagents such as the HCl used in leaching, the reduction of energy consumption through the development of a low—temperature, ambient pressure leaching process, the reduction of chemical diversity, the prevention of waste products (e.g. gypsum produced during neutralization), and the electrification of the final purification of nickel and cobalt.

Ferronickel case study

The ferronickel, which was kindly provided by Larco, first underwent hydrochloric acid leaching at oxidizing conditions, generating a pregnant leach solution (PLS) which is rich in both iron (70 – 80 g/L) and nickel (20 – 25 g/L). This leaching was performed at atmospheric conditions, using temperatures of 80 °C and leaching times of around 3 hours.

In a next step, iron and hydrochloric acid was be removed simultaneously through five counter-current stages of solvent extraction with tri-n-butyl phosphate (TBP), producing a purified nickel chloride solution for further recovery of battery-grade nickel.

This extraction process has been successfully applied on mini-pilot-scale mixer-settlers, ran in continuous mode. In a next phase, TBP is regenerated through stripping with water, while HCl is regenerated from the strip raffinate. The process hence maximizes the circularity of the reagents.

References

(1) Binnemans, K.; Jones, P. T. The Twelve Principles of Circular Hydrometallurgy. J. Sustain. Metall. 2022, 9 (1), 1–25. https://doi.org/10.1007/s40831-022-00636-3

Acknowledgements

Special thanks to Clara Vermoere, Seyedehmaryam Sadeghi, Azadeh Ghannad Asadollahi and Almir Olovcic for their help during this project. This project has received funding from the European Union’s Framework Programme for Research and Innovation Horizon Europe under Grant Agreement No. 101058124 (https://enicon-horizon.eu/)

ICHS 2024 – 1st International Circular Hydrometallurgy Symposium – 9-11 September 2024 (cirmet.eu)

Inspired by the position paper "The Twelve Principles of Circular Hydrometallurgy" (i.e. the recipient of the TMS EPD/LMD Journal of Sustainable Metallurgy Best Paper Award), ICHS gives the floor to world-leading academic and industrial hydrometallurgists to provide visionary lectures on what these principles may mean for the future of hydrometallurgy, knowing that, without metals, there is no transition to a climate neutral economy! The event will take place in the majestic LAMOT Congress & Heritage Centre in the historical city of Mechelen, Belgium.

Speaker line-up for ICHS 2024: David Robinson, Kerstin Forsberg, Markus A. Reuter, David Dreisinger, Päivi Kinnunen, Jacques Eksteen, Kathy Sole, Ryan Ravenelle, George P Demopoulos, Mari Lundström, John Monhemius & Anne-Gwénaëlle Guezennec, Koen Binnemans

Organisers: The Symposium is organised by SOLVOMET R&I Centre in the context of Koen Binnemans' ERC AdG CIRMET project and the Horizon Europe CICERO Project. Furthermore, the Symposium is supported by SIM2 KU Leuven and three other key European projects dealing with (a.o.) circular hydrometallurgy of energy transition metals: Horizon Europe EXCEED & LITHOS, Horizon Europe ENICON.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant