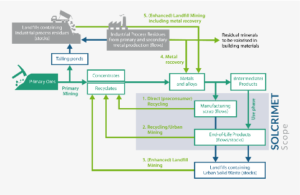

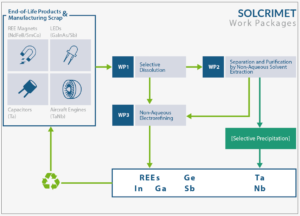

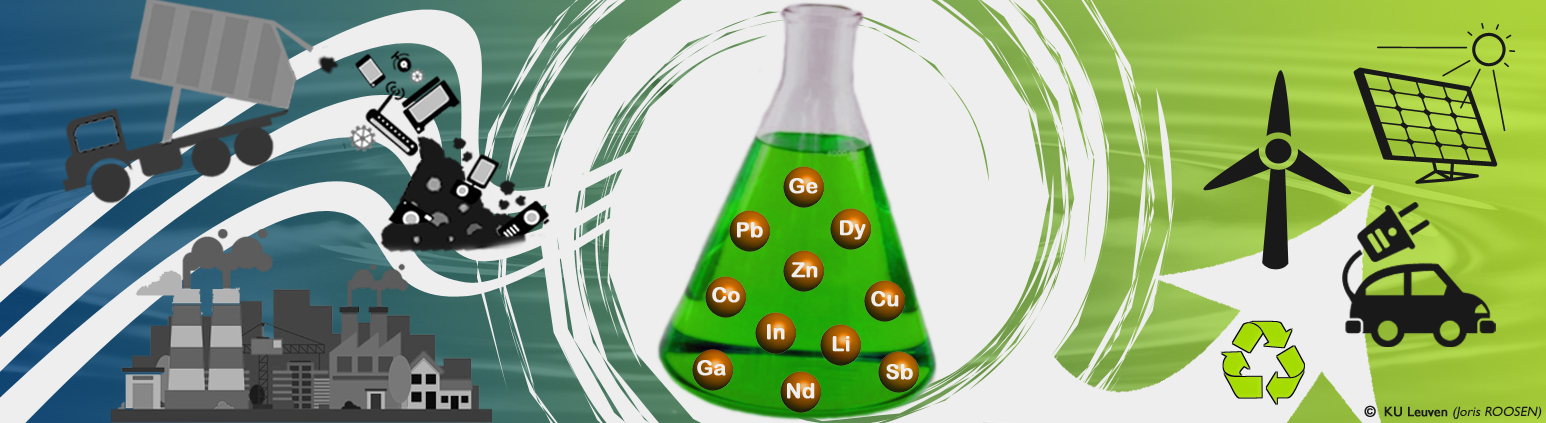

SOLCRIMET, representing “Solvometallurgy for critical metals”, is the ERC Advanced Grant Project of Prof. Koen Binnemans and his team at KU Leuven. SOLCRIMET targets solvometallurgical solutions for the selective recovery of critical metals from urban End-of-life waste streams.

SOLCRIMET Highlights

- For most of its hi-tech applications (smart phones, electronics…) and cleantech applications (wind turbines, electric cars…) Europe is heavily dependent on countries like China who dominate the productions of the metals that are needed for these applications.

- In case a metal is economically very important and it suffers from a high supply risk (meaning that the easy supply of this metal can be blocked), such a metal is called a “critical metal”.

- To become less dependent on countries like China for these critical metals, Europe needs to develop novel technologies that are able to remove and recover the critical metals that are present in End-of-Life products that are available in Europe, such as End-of-Life electric cars, smart phones or wind turbines.

- SOLCRIMET develops new technology, based on environmentally-friendly, non-water nor acid-containing solvents that selectively recovers critical metals from a diversity of End-of-Life products.

- SOLCRIMET will make sure that the development and production of hi-tech and clean-tech products in Europe will become less dependent on the import of expensive, critical metals from countries like China.

- SOLCRIMET will contribute to the required transition from the present, fossil fuel based linear economy towards a climate-friendly, circular economy in Europe.

Why solvometallurgy?

Solvometallurgy is complementary to pyrometallurgy and hydrometallurgy. However, this new approach offers several advantages. Firstly, the consumption of water is very limited offering a major advantage in regions where there is a shortage of water. Secondly, the leaching and solvent extraction can be combined in a single step, which leads to simplified process flow sheets. Thirdly, solvent leaching can be more selective than leaching with acidic aqueous solutions, leading to reduced acid consumption and less purification steps. Fourthly, solvometallurgy is useful for the treatment of ores that are rich in soluble silica (such as eudialyte) as no silica gel is formed. Hence, solvometallurgy is in a position to help develop near-zero-waste metallurgical processes, and with levels of energy consumption that are much less than with high-temperature processes. The reader is referred to the Binnemans & Jones position paper on solvometallurgy where the benefits of solvometallurgy are described in greater detail [K. Binnemans & P.T. Jones, Solvometallurgy: an emerging branch in metallurgy, Journal of Sustainable Metallurgy, 2017, DOI 10.1007/s40831-017-0128-2 – download here]

SOLCRIMET Cordis webpage

http://cordis.europa.eu/project/rcn/203410_en.html

Acknowledgements

The research leading to SOLCRIMET results received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation Programme: Grant Agreement 694078 — Solvometallurgy for critical metals (SOLCRIMET).

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant