Separation of GaCl3 from other associating chloride compounds (e.g. AlCl3, SbCl3 and InCl3) is generally achieved by hydrometallurgical processes. Zheng Li (SOLVOMET KU Leuven) and colleagues from KU Leuven and University of Texas at Austin found that GaCl3 can be efficiently extracted by anhydrous n-dodecane from a solid mixture of GaCl3 and AlCl3; GaCl3 in the loaded n-dodecane phase can be stripped by solid NaCl through formation of NaGaCl4. The extraction of GaCl3 by n-dodecane in combination with its stripping by NaCl, is a solvometallurgical process that is essentially different from the hydrometallurgical processes for the separation of GaCl3 and AlCl3. The work has been published in Ind. Eng. Chem. Res.

Known as “the backbone of electronics industry”, gallium is used widely in optoelectronics and particularly for semiconductors. Purification of gallium via a chloride route involves the separation of GaCl3 and associating chloride compounds, including AlCl3, InCl3 or SbCl3. Hydrometallurgical process, such as solvent extraction and ion exchange, are the main processes for the separation of gallium from these associating elements. While established, these processes usually require multiple separation stages due to the similar affinity of these compounds to extractants and ion exchangers.

Full reference of paper

Zheng Li, Brent Bruynseels, Zidan Zhang, and Koen Binnemans, Separation of GaCl3 from AlCl3 by Solid−Liquid Extraction and Stripping Using Anhydrous n‑Dodecane and NaCl, Ind. Eng. Chem. Res. 2019, 58, 12459−12464, DOI: 10.1021/acs.iecr.9b00768

Acknowledgements

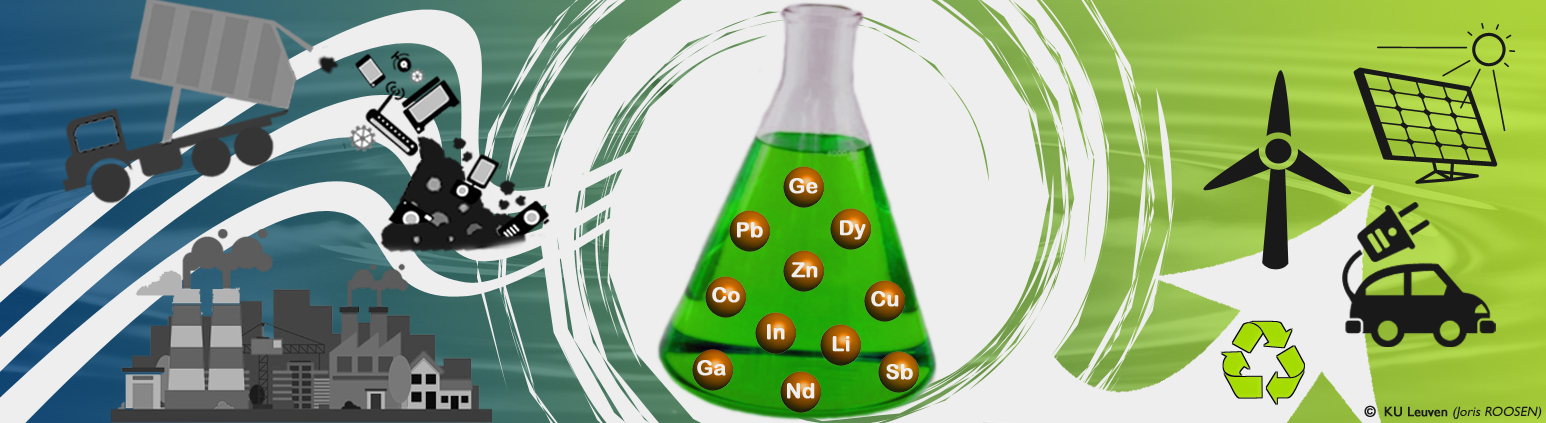

This research was supported by the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation Programme: Grant Agreement 694078 [Solvometallurgy for critical metals] (SOLCRIMET). Liubov Lukina is acknowledged for help with translating Russian papers.

Find out more about Zheng Li in this interview.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant