Antimony was selectively leached from a lead-rich industrial process residue called ‘dross’, and recovered as an antimony oxide chloride (Sb4O5Cl2), which can be used as a component in flame retardants or as an anode material in aqueous chloride batteries. This work by SOLVOMET/SIM² KU Leuven researchers was published in ACS Sustain. Chem. Eng.

Scope of the manuscript

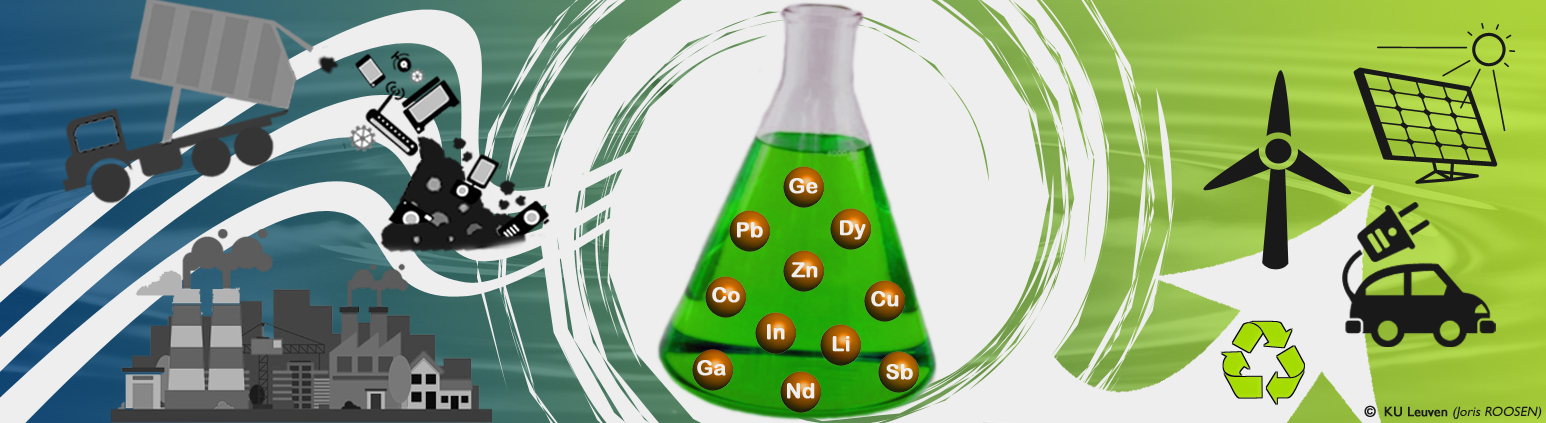

Lead-acid (LA) batteries for use in cars are one of the main applications of lead. Lead in such batteries contains significant amounts of antimony to harden the lead.

End-of-Life LA batteries have high collection and recycling rates and the lead in these spent batteries is typically recycled via pyrometallurgical processes. Lead recycling companies (secondary lead smelters) produce pure lead from LA batteries and other lead-containing waste materials via a melting-drossing-refining process.

Dross is one of the waste residues generated during the lead recycling process. It is composed mostly of antimony and lead (30 wt% each). At present, the drosses are used in reduction processes to create antimonial lead.

Since this use is expected to decrease, there is a risk for this material to become obsolete in the future. The challenge is to develop an efficient and sustainable process for the separation of antimony from the dross, so that the rest of the residue could be further processed for lead recovery.

Take home message

Solvometallurgical leaching was applied on drosses from a lead recycling plant to selectively recover antimony. After screening various chloride-based organic lixiviants, hydrochloric acid in ethanol was found to give high leaching efficiencies of antimony with minimal co-dissolution of lead.

The low dissolution of lead in this lixiviant was due to the low solvating power of the low-polarity molecular solvents for the produced lead(II)-chloro complexes, which resulted in a precipitation of lead(II) chloride (PbCl2).

Using ethanol instead of water as a solvent for hydrochloric acid not only improved the selectivity towards antimony over lead but it also required less chloride concentration to leach similar amounts of antimony, which would significantly diminish the usual corrosion issues faced by the industries for using high chloride concentrations.

The antimony and lead in the dross were present as a mixture of various mineral forms. By using 2 mol L−1 hydrochloric acid in ethanol, the trivalent antimony containing minerals (i.e., PbO·Sb2O3, Mg/ZnO·Sb2O3 and PbSi2O5·1.6H2O) were fully leached but the stable pentavalent antimony mineral bindheimite (2PbO·Sb2O5) and trivalent valentinite (Sb2O3) were only partially leached or not leached at all.

The dissolved lead precipitated as lead(II) chloride (PbCl2). The 2 mol L−1 HCl in ethanol achieved highly selective leaching of antimony (90%) over lead (0.4%). The antimony in the PLS was recovered by hydrolysis precipitation using water, producing a pure antimony oxide chloride (Sb4O5Cl2).

Full reference of paper

Palden, T.; Machiels, L.; Regadío, M.; Binnemans, K. Antimony recovery from lead-rich dross of lead smelter and conversion into antimony oxide chloride (Sb4O5Cl2). ACS Sustain. Chem. Eng. 2021, 9, 5074–5084. https://doi.org/10.1021/acssuschemeng.0c09073.

Acknowledgements

The authors of this work acknowledge the Strategic Initiative Materials in Flanders (SIM) for the financial support (SBO-SMART: Sustainable Metal Extraction from Tailings) with grant no. HBC.2016.0456. The authors also wish to acknowledge funding from European Commission’s H2020 – Marie Sklodowska Curie Actions (MSCA) − Innovative Training Networks within the SOCRATES project under the grant agreement no. 721385 (Project website: http://etn-socrates.eu). This work reflects only the authors view, exempting the community from any liability.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant