Following a 25-year, Vice-President level career at Umicore mainly focusing on operations, process technology, engineering and business development, Dr. Ben Gilliams decided to make a major career switch and return to his alma mater, KU Leuven. Exactly 25 years after obtaining his PhD at the Department of Chemistry in Leuven, Ben started on January 9, 2023, as Senior Valorisation Director at SOLVOMET ISC (SIM² KU Leuven). Given his impressive industrial track record in the field of battery raw materials (refining and recycling) as well as precious metal refining, he will massively strengthen the SOLVOMET ISC team, allowing to make its research even more impactful than today. SIM² Director and SOLVOMET Innovation Manager Peter Tom Jones sat down with Ben in order to better understand why he made the switch from a top-level industry job (back) to KU Leuven. In this interview you will get to know more about Ben’s industrial track record, his view on the role of pyrometallurgy versus hydrometallurgy or the mining & refining versus recycling conundrum, and his main challenges for the future.

A very warm welcome to KU Leuven Ben! We are absolutely delighted to take this maiden interview with you as our new Senior Valorisation Director within the SOLVOMET Industrial Service Centre (ISC). Kicking off with the obvious question, you decided to move from a high-level “Vice-President” (VP) position at the world-leading “circular materials technology company” Umicore to an “academic” research valorisation position at SIM² KU Leuven. What triggered you to make this rather unconventional career switch and seek pastures new?

Thanks for your warm welcome Tom, that’s much appreciated. My career switch, indeed, might be considered as a bit unconventional, but it just felt right to do something different at this stage of my life. But let’s be clear here; although I have just blown 50 candles, I would certainly not call this a midlife crisis. Instead, it is much more about a desire to use and spend my experience, my energy and time differently, exploring additional horizons in order to give an extra dimension to my career and, in general, “to live more”.

Furthermore, it’s something of a circular thing as well – feels a bit like “closing the loop”: after starting here as a MSc and PhD student decades ago I now return to my Heimat at the KU Leuven Department of Chemistry. Although I must admit, I hardly recognized the place after 25 years: so many new building projects at the Campus! Very impressive and motivating.

Going back to your former Umicore job, what have been your key activities during the past 20–25 years?

After finishing my PhD in Chemistry in 1998, I immediately started working in Umicore’s analytical and R&D lab at Hoboken Precious Metal Refining. After a few years I moved into the plant and held several production and operational roles focusing on specialty metals and precious metals.

In 2010 I moved to Bruges. Umicore acquired a small family-owned company; for me an opportunity to take up my first role in general management. Afterwards, my role expanded to catalysts and carboxylates in Bruges and the USA. In 2015 I moved into the cobalt and nickel world, with a first step taken in Umicore’s Cobalt and Specialty Metals site at Olen. There I acted as the Plant Director. In 2017 I went global again, as Global Business & Technology Director Inorganics, with responsibilities in EU, USA and Asia.

As of 2018, I was offered a VP position in Umicore, first in the Business Unit (BU) “Cobalt & Specialty Materials” and, more recently, the BU “Rechargeable Battery Materials”. Besides the day-to-day operations and management, a key part of my job – supported by a great team of people – comprised the development of technology roadmaps and business opportunities.

What would you consider as the highlights of your Umicore trajectory?

That’s always a tricky question to answer of course, isn’t it? But the debottlenecking projects in the PGM refinery in Hoboken at the time Umicore acquired parts of Degussa/OMG would certainly need to be mentioned here. Other highlights include my experiences in Bruges and my first years in the cobalt/nickel refining world, which triggered my entrepreneurial skills, having the luxury that my first boss really was a great coach, mentor and entrepreneur, inspiring me to really think and act outside the box.

Overall my Umicore journey was a steep learning curve and a fun ride; I was blessed to have worked for and be inspired by a few wonderful mentors.

Given the fact that you have worked so long for a company that is renowned for its urban mining and recycling narrative: what’s your take on the role of recycling versus primary mining of energy-transition metals. In particular with respect to the battery metals.

My personal point of view on this is a very simple one and rather straightforward: recycling and primary mining go hand in hand, both from a chemical competency point of view as well as driven by the fact they are both needed to secure the battery materials supply chain. As reported by so many different international organisations, in view of meeting the climate targets the demand for clean mobility materials is going to skyrocket in the coming decades. The amounts of nickel, cobalt, manganese and lithium compounds that will be needed to feed the transformation towards clean mobility & energy will be gargantuan.

The production of these metals and salts needs to be done in a sustainable way: hence, recycling needs to kick in at a certain moment in time, complementing the upcoming scarcity of primary raw materials, (that need to be mined and refined). Given the massive needs for fresh metal input and the current lack of End-of-Life battery streams, primary mining will remain predominant for some time. Still, along that pathway, recycling of End-of-Life batteries should start to take over. In the transitional period, there will also be a massive need for the recycling of battery production scrap. The volumes of this type of pre-consumer scrap will become quite significant in the coming years. This is due to the rapid establishment of battery gigafactories all over the world. The players in this ecosystem can and should use this material to optimise their processes, not only to blend in these recycled metals from this production scrap, but also to be ready for treating the End-of-Life batteries, once they become available in larger quantities. High raw material prices will, furthermore, boost the economic viability of these recycling processes.

As regards battery recycling there has been a lot of discussion about the use of pyrometallurgy versus hydrometallurgy? How do you see this evolving?

My humble opinion is that, generally speaking, pyrometallurgy and hydrometallurgy are like jing and jang; hence they will need to supplement each other. It is of course evident that less complex battery waste streams require less complex (and less expensive) processing to transform the metals and re-integrate them back into the battery materials value chain. However, for more complex materials, such as End-of-Life battery streams, a combination of both competencies will likely provide the better answer. That being said, I think it is fair to state that a lot of the players, both industrial and academic ones, are still working and studying very hard to find the “better” economical and sustainable answer for this “pyro versus hydro” conundrum.

What can be the role of universities and research centres in metallurgical processes for critical metal refining?

Any kind of metallurgical solution for metal refining and recycling needs to be based on in-depth scientific knowledge of both base and critical metals, both in terms of pyrometallurgical and hydrometallurgical expertise. During the past decades there has been, at least in my view, too little attention for nurturing and consolidating fundamental metallurgical expertise both in industry and academia.

Take for instance the rare earths. In the past we had such a rich community of both industrial and academic experts in Europe. However, as these experts were retiring they were not replaced with new ones. The expertise was gradually lost. We needed a global rare earth crisis before we woke up and started training new rare-earth scientists and engineers again. The recent announcement by LKAB about its newly discovered rare earth deposit in Kiruna, North Sweden, is great but that’s only a start. We still need to do the mineral processing, metal extraction and refining. We need multiple expertise domains to do that properly.

Hence, given the massive criticality risks for not only the rare-earth elements but also the battery metals, it is clear that, in an increasingly turbulent world, it is essential that Europe (re)builds this metallurgical expertise, both in industry and in academia.

I am convinced that SOLVOMET ISC is a wonderful example of such a research environment where both fundamental and applied chemical metallurgy expertise is being continuously developed. So, clearly, that’s the role of universities and research centres: use such a unique, science-deep, metallurgical expertise to support industry in developing more sustainable metal recycling and refining solutions.

Personally, I have the impression that there is often a mismatch between industry needs and academic activities when it comes to metal recycling and refining solutions? Do you agree with this statement and, if so, how can we overcome this schism?

Using the word “mismatch” might be an exaggeration. But I guess you refer to the fact that some academic groups are developing flowsheets with rather exotic, non-REACH-compliant chemicals that are too expensive to be commercialised. In that case there could indeed be a schism between the fancy flowsheets published in academic journals and what is really required in industry. The latter comprises (1) upscalability, (2) favorable process economics and (3) demonstrated sustainability, which needs to go hand in hand with the successful permitting side of the equation regarding environment, health and safety.

Yes, indeed, the academic hype around ionic liquids and deep-eutectic solvents presents a perfect example of this mismatch. Despite 20 years of research on these kind of flowsheets, none of these have ever been industrialised. That being said, I personally believe that industry could also do more to make sure that metallurgical academic researchers are working on the right questions and challenges. Too much secrecy on behalf of companies doesn’t always help to guide the research in an industrially-realistic, yet scientifically-innovative direction. Do you see any possibilities here how industry could work in a more synergistical relationship with academia?

I fully agree with you Tom, but we also need to understand there is a thin line between overzealous secrecy and naïve openness. We have to respect that there is a genuine economical aspect to consider, with cut-throat competition at play. Hence, there is a reason why industrial players are sometimes reluctant to share key info or be too transparent.

That being said, I’m 100% with you on a more intense collaboration and interaction between industry and academia. We are in this together; not only for fundamental and applied research to be meaningful, but also because both parties have an important task and responsibility in training and educating people – filling the pipeline and contributing to the overall “war for talent” in our own region.

Coming back to your new role as Senior Valorisation Director at SOLVOMET ISC, what will be your main activities? How will you spend your days from now on.

One of the roles I am really looking forward to is to coach the junior researchers, research experts and research managers in their on-going projects. I want to make them understand better how industrial processes are developed in reality. In that way they can make smarter research choices while developing their hydrometallurgical flowsheets, in view of either primary mining, metal recovery from secondary residues or intermediates, or urban mining and recycling.

Concurrently, I am eager to work together with the SOLVOMET ISC Group leader, Prof. Koen Binnemans himself, and the senior members to co-develop new European, Flemish and bilateral projects in collaboration with other strong research groups and companies worldwide. In this framework, I can’t wait to get stuck in the on-going development of the new SOLVOMET ISC hydrometallurgical mini-pilot hall in the brand new Bio-Incubator building in Leuven. I will be looking forward to the formal kick-off event for this milestone for SOLVOMET. I will be happy in trying to contribute in making this a real success story and platform for further growth.

When will you be satisfied with your work?

Well Tom, as said earlier, we are living in a very challenging but also fascinating time where all these environmental megatrends on clean mobility, clean energy and scarcity of metals and materials really come into play – we are confronted with them on a daily basis. I am convinced that “spot-on, industrially applicable research” and closer collaboration between research centres and industry is a must and should make the difference to further evolve towards a more sustainable ecosystem. If we – as the SOLVOMET Group – can, let’s say, “move the needle a bit”, I would be very proud and satisfied.

Apart from the contant need to secure new research project funding for SOLVOMET ISC, I want to stress that one of my main drivers to take up this new challenge is “to fill the pipeline of talent”. I want to use my background, including my people development skills, in making sure there is a constant output of exceptionally-well trained MSc students, PhD students and young postdocs who can go and work in the metallurgical industry in Flanders, Belgium and Europe and why not worldwide. Looking at the present composition of the SOLVOMET Group, I must say I am impressed with the already available talent, enthusiasm and cultural diversity at hand. But we can never rest on our laurels. Things can change quickly.

I absolutely agree. The same goes for football teams. Success today does not mean success tomorrow. To close off the interview, is there something final you want to convey?

Personally I have been blessed in my career with being mentored by some remarkable people in Umicore, both in terms of managerial, personal development and business development skills. It is my sincere hope that I can now pass on some of my experiences and skills to younger people so that one day they will say the same thing about me. A little bit of impact in that matter would be awesome.

Can a person wish anything more than that? Thank you for this interview. We look forward to what comes next!

[Interview: Peter Tom Jones, SOLVOMET ISC/SIM² KU Leuven; Photos: Elisabeth De Decker, SOLVOMET ISC]

Who is Dr. Ben Gilliams?

Ben Gilliams obtained his PhD in Chemistry in 1998 at the Department of Chemistry at KU Leuven (in collaboration with Agfa-Gevaert). The topic of his thesis was “On the Effect of Coordination on the properties of Rh & Ir compounds”. Subsequently, he moved to Umicore where he worked for a period of almost 25 years, taking up various roles in operations, process technology, engineering, projects and business development up to Vice-President level. Throughout his career, Ben has built up a broad business experience, working in several business environments, such as Precious Metals Refining, Cobalt & Specialty Materials and Rechargeable Battery Materials, with responsibilities in Europe, North-America and Asia. As of January 2023, Ben started working at SOLVOMET ISC KU Leuven as Senior Valorisation Director. Ben loves to enjoy the good life, both in going out with friends discovering great food accompanied with a nice wine or beer, at the same time being keen on a number of sports including running, padel, tennis and skiing.

Want to know more about SOLVOMET ISC and SIM²?

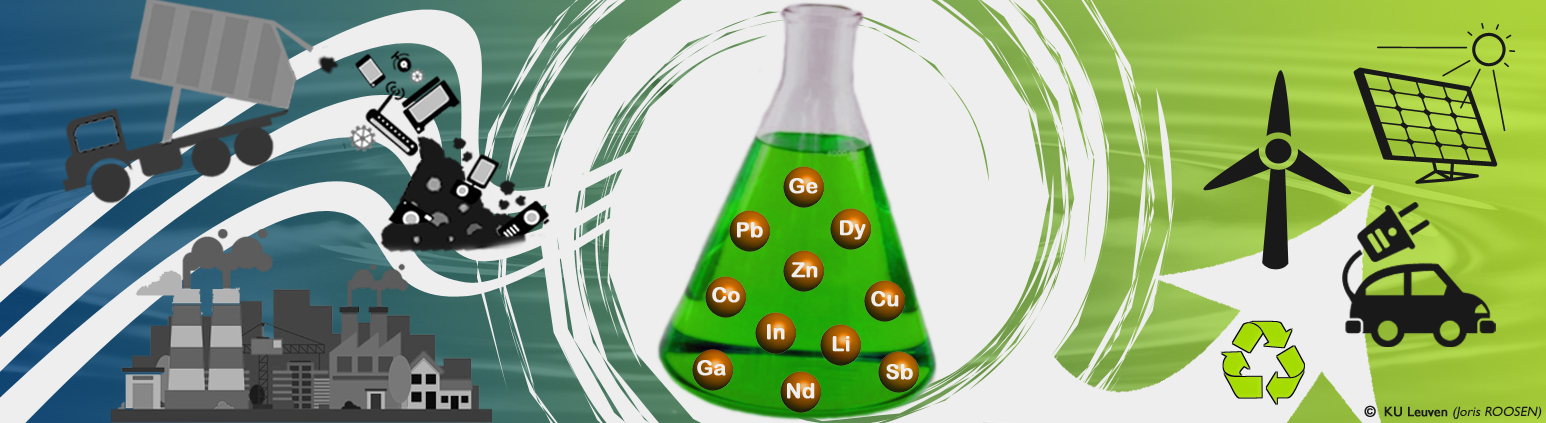

SOLVOMET ISC is KU Leuven’s Industrial Service Centre for Circular Hydrometallurgy led by Prof. Koen Binnemans and Dr. Peter Tom Jones. SOLVOMET ISC supports mining, metallurgical & recycling companies in the development of more sustainable (circular, low-energy input) hydrometallurgical processes, using state-of-the-art lab & mini-pilot scale experimental facilities. You can find out about SOLVOMET’s expertise, team and project types through this presentation: SOLVOMET ISC Corporate Presentation 2022

- SOLVOMET ISC website: https://solvomet.eu/

- SOLVOMET ISC LinkedIn page: SOLVOMET ISC: My Company | LinkedIn

SIM² KU Leuven is the KU Leuven Institute for Sustainable Metals and Minerals (SIM² in short). SIM² is one of the official KU Leuven Institutes that were endorsed by the KU Leuven Academic Council. SIM² has more than 240 members, coming from a wide range of (interdisciplinary) research groups and departments at KU Leuven. SIM²’s missions is “to develop, organise & implement problem-driven, science-deep research & future-oriented education, contributing to the environmentally friendly production & recycling of metals, minerals & engineered materials, supporting (…) a climate-friendly, circular-economy”.

- SIM² website: https://kuleuven.sim2.be/

- Follow SIM² on LinkedIn: SIM2 KU Leuven: My Company | LinkedIn

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant