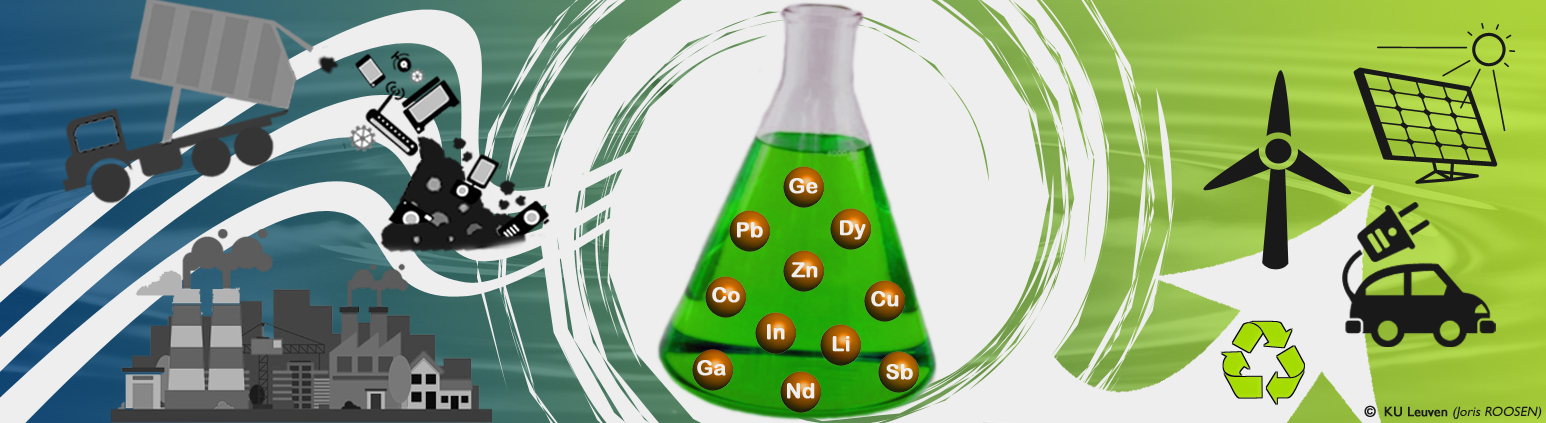

Europe strongly depends on the import of metals from China for its clean technologies. Researchers of the EU Horizon 2020 SOCRATES project try to reduce this dependence by finding new eco-friendly ways to recover these metals from industrial process residues. The SOCRATES team has now just released a new animation video featuring SOCRATES PhD students as presenters. This film was made in collaboration with Storyrunner (Leuven, 4-7-2017)

The bottom ashes of incinerators, or the waste from zinc and copper production: all of these residues have unexploited potential. The sludge from zinc production, for instance, contains valuable metals and minerals that are lost as the waste is stored in landfills. The researchers of the EU SOCRATES project are developing zero-waste methods to recover the valuable metals that can be used for cleantech technologies. Once these metals have been recovered, the scientists transform the remaining minerals into an eco-friendly cement for houses and streets – today’s waste, tomorrow’s resources. Watch the video here: https://www.youtube.com/watch?v=9ilrNeKG4D8

SOCRATES Scope

The European Training Network for the Sustainable, zero-waste valorisation of critical-metal-containing industrial process residues (SOCRATES) targets ground-breaking metallurgical processes, incl. plasma-, bio-, solvo-, electro- and ionometallurgy, that can be integrated into environmentally friendly, (near-)zero-waste valorisation flow sheets. By unlocking the potential of these secondary raw materials, SOCRATES contributes to a more diversified and sustainable supply chain for critical metals (cf. Priority area 3 in EC Circular Economy Action Plan; COM(2015)614/2). The SOCRATES consortium brings together all the relevant stakeholders along the value chain, from metal extraction, to metal recovery, and to residual matrix valorisation in added-value applications, such as supplementary cementitious materials, inorganic polymers and catalysts. To maximise applicability, SOCRATES has selected four commonly available and chemically complementary residue families: (1) flotation tailings from primary Cu production, (2) Fe-rich sludges from Zn production, (3) fayalitic slags from non-ferrous metallurgy, and (4) bottom ashes from incineration plants. As a basis for a concerted effort to strengthen the EU’s critical-metal supply chain for Ge, In, Ga and Sb, SOCRATES trains 15 early-stage researchers (ESRs) in technological innovation: metal extraction (WP1), metal recovery (WP2), residual matrix valorisation (WP3) and integrated assessment (WP4). By training the ESRs in scientific, technical and soft skills, they are the next generation of highly employable scientists and engineers in the raw-materials sector.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant