Fossil-free steel? Trucks of 313 tonne capacity electrically driven? Industry streams recycled for research? A smelter almost 100 years old that has become one of the largest recyclers of e-waste or the so-called world’s greenest battery factory? All of these ideas happen at once in a place where you could be covered by snow for weeks or where it does not get dark at all during summer time.

During 4 days, young students and researchers from 9 different institutions located in six countries across Europe gathered in Northern Sweden to visit mines, smelters, R&D centres and industrial plants. The visits took place in the framework of the PROMETIA Tech Tour 2022 [1].

The visited companies are among the top-drivers of the raw materials industry and the energy transition in Europe: LKAB, Boliden Aitik, Boliden Rönnskär, Swerim, Luleå University of Technology and Northvolt Ett. The articulation between these parties gives valuable lessons on how the rest of European countries can push their boundaries to achieve the goals of a circular economy and a sustainable future.

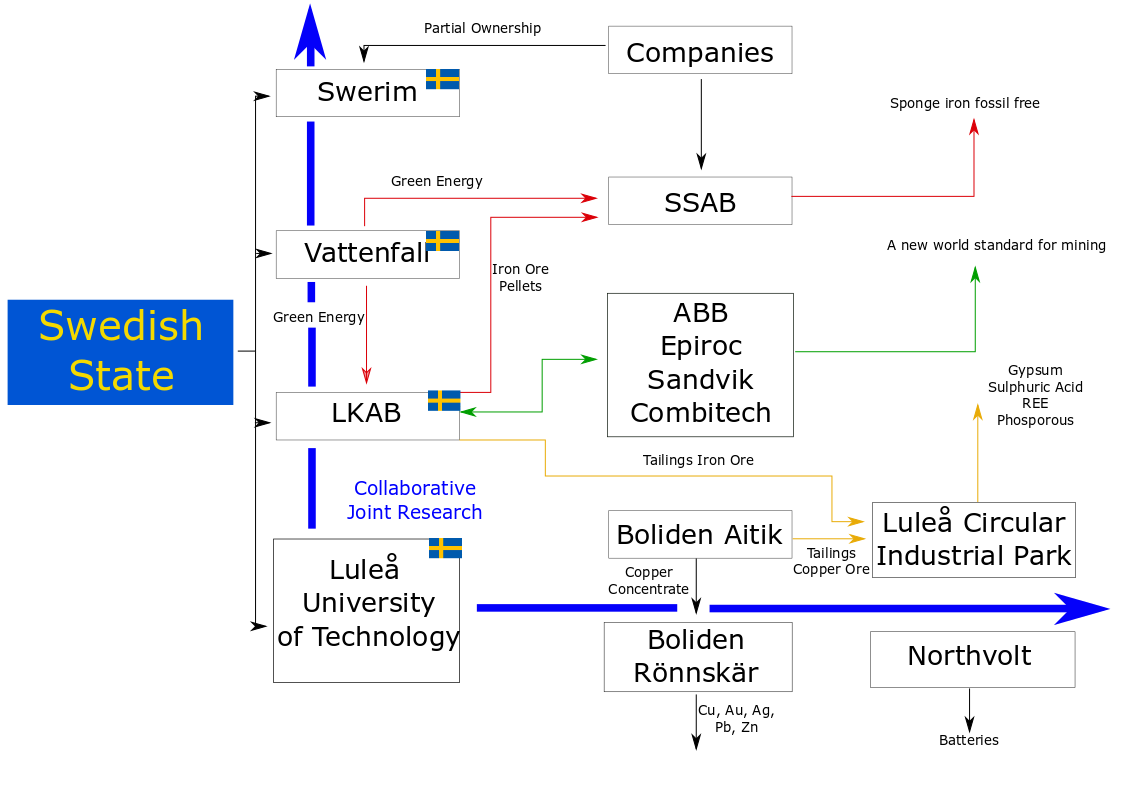

The Swedish state partially or completely owns many of the key companies in the sector, throughout the value chain. This is the first lesson we can draw:

Policy goals can be better reached if the government is an active party, participating not just as a framework designer, but as a booster and partner.

One of these companies is LKAB, founded in 1890 and fully owned by the Swedish state, produces around 80% of all iron ore in the European Union. Their carbon-free strategy is based on three fundamental areas of innovation. In an industry responsible for 7–9% of global CO2 emissions [2], all initiatives are important.

Let’s see how these initiatives are interconnected with the companies visited during the PROMETIA Tech Tour:

Setting a new world standard for mining

As mining will go deeper and ore grades decrease, innovation in mining is the first step. A joint partnership with 4 major industrial Swedish companies (ABB, Epiroc, Sandvik and Combitech) will help in the digitalisation, automation and electrification of the industry [3].

Carbon-free sponge iron

Vattenfall (another 100% Swedish state-owned company [4]) and SSAB (a Swedish-based steelmaking company in which LKAB is a major shareholder [5]) designed a process to replace coal by hydrogen in steel production. As of 2045, LKAB production will be moved towards this end-product only, and the project has the opportunity to reduce Sweden’s total CO2 emissions with at least 10% [6].

Swerim

On the other hand, SSAB is part of a conglomerate of Swedish companies that own 51% of Swerim (Swedish metal research institute). Swerim provides expertise in a different range of metallurgical fields with a strong background in large-scale pilot testing. Moreover, it is located just next to the SSAB installations in Luleå, which provides an opportunity to use heat and gases produced in the steelmaking process for the research projects developed at Swerim. And yes, the Swedish state also has 20% of the ownership here. This bring us to the second lesson:

Build an ecosystem! Circularity can be easier if you can participate in strategic decisions and revenues in/along the cycle of your product.

Critical minerals

The tailings of the iron ore production can become a potential resource of many of the minerals needed nowadays. A partnership was announced with Boliden’s Aitik [7], the most efficient copper mine in the world, to explore the use of pyrite concentrate (coming from waste) in the recovery of these minerals from tailings.

With a production of 43 Mt/year of ore, which needs to be upgraded from 0.2% Cu to 25% Cu, major streams of waste are generated. Hence, this partnership is a key move. Boliden itself began to make hybrid systems in its 313 tonne capacity trucks to reduce fuel consumption and emissions in a fleet driven mostly by women.

Luleå was proposed as the place for this idea to come to fruition [8]. Talings from Aitik will help to produce H2SO4 that in turn will be used to process the tailings of LKAB. The expected outcome is: Cd-free phosphorous to supply five times the Swedish demand for fertilizers, 30% of the REE demand of the EU and the full Swedish demand for gypsum in its construction industry.

Hence, we can outline a third lesson here:

Talk with your partners. Building solutions together, makes a stronger industry for mutual benefit.

LKAB’s Malmberget Conveyor belt. Photo courtesy Bastien Duplantier

Boliden Rönnskär

Additional companies in Northern Sweden include Boliden’s smelter Rönnskär (19% of total production coming from recycling, 81% zinc produced from secondary materials) and Nothvolt Ett plant construction (40 GWh/year powered 100% with renewable energy in manufacturing), both located in Skellefteå.

Likewise, Northern Sweden can also boost Luleå University of Technology, which was established in 1971 and which nowadays is a strategic partner in this ecosystem through collaborative research. This bring us to the final lesson:

Be a good neighbor. The more friends you have, the better. The ecosystem can only become effective if there is a clear collaboration with all stakeholders, including the Swedish state.

Bio Carlos Quintero

Carlos Arias-Quintero is a geological engineer with a triple diploma from the Erasmus Mundus Emerald Master in Resources Engineering (University of Liege, University of Lorraine and Lulea University of Technology). After working in consultancy for mining in Colombia, and in mineral processing research in France, he recently joined the SOLVOMET Group at SIM² KU Leuven as a geometallurgist. (Photo: Aitik’s Caterpillar 795F truck. 313 tons load capacity. Photo taken CAQ)

Carlos Arias-Quintero is a geological engineer with a triple diploma from the Erasmus Mundus Emerald Master in Resources Engineering (University of Liege, University of Lorraine and Lulea University of Technology). After working in consultancy for mining in Colombia, and in mineral processing research in France, he recently joined the SOLVOMET Group at SIM² KU Leuven as a geometallurgist. (Photo: Aitik’s Caterpillar 795F truck. 313 tons load capacity. Photo taken CAQ)

References

[1] https://worldsteel.org/publications/policy-papers/climate-change-policy-paper/

[2] https://lkab.com/en/what-we-do/our-transformation/a-new-world-standard-for-sustainable-mining/

[3] https://group.vattenfall.com/who-we-are

[4] https://www.ssab.com/en/company/investors/ssab-share/shareholders

[5] https://www.hybritdevelopment.se/en/

[6] https://ree-map.com/lkab-boliden-collaborate/

[8] https://prometia.eu/the-association/

[Featured image: Aitik’s P&H L-2350 Wheel loader (The biggest of the world). 40,5 cubic meters capacity. Photo courtesy of Bastien Duplantier]

PROMETIA?

PROMETIA is a non-profit association that promotes innovation in mineral processing and extractive metallurgy for mining and recycling of raw materials [8]. In the object of its mission, the association gathers industries and R&D institutions to promote collaboration and networking. The Tech Tour is the space where young professionals and researchers can share insights and their contributions to promote raw materials accessibility within Europe. SIM² KU Leuven is an official member of PROMETIA.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant