Within the framework of the ETN DEMETER project rare-earth permanent magnets were treated with solvometallurgical solutions of Br2 in organic solvents to remove the metallic coating prior to direct recycling. A comparison with a 2 M HNO3 treatment proved the advantages of the solvometallurgical process. The work is published in RSC Advances.

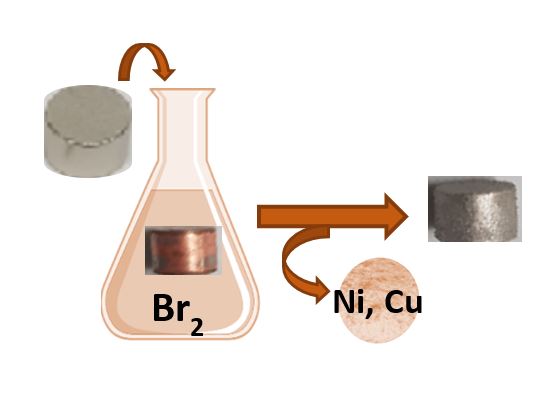

Successful direct recycling routes, mainly via hydrogen decrepitation, are known for both Nd‒Fe‒B permanent magnets and Sm‒Co permanent magnets. Often the magnets are coated by a nickel-copper-nickel coating to prevent corrosion of Nd‒Fe‒B magnets and chipping of Sm‒Co magnets.

However, this coating does not contribute to the magnetic properties and only ends up as a contamination in the recycled magnet powder, reducing the performance of the secondary-produced magnet.

New method developed

DEMETER researchers developed a solvometallurgical process for removal of the metallic coating prior to the direct recycling. In particular, mixtures of bromine in different organic solvents (DMF, EG, EtOAc, EtOH, MeOAc) were tested on both Nd‒Fe‒B Sm‒Co bulk permanent magnets.

The solvents were chosen according to their polarity and their Gutmann donor’s number (which measures the solvation capability of a solvent). Viscosity also showed to have a relevant influence on the magnet coating removal.

The best performing mixtures were bromine in EtOH and in DMF, but EtOH has to be preferred since DMF is not a green solvent. A comparison with 2 M HNO3 treatment proved the advantages of the solvometallurgical bromine-based process in the removal of the nickel-copper-nickel coating from both Nd‒Fe and Sm‒Co permanent magnets, without co-dissolution of the magnet alloy.

Full reference paper

Martina Orefice, Anas Eldosouky, Irena Škulj and Koen Binnemans, Removal of metallic coatings from rare-earth permanent magnets by solutions of bromine in organic solvents, RSC Adv., 2019, 9, 14910-14915, DOI: 10.1039/C9RA01696A

Acknowledgements

The research leading to these results received funding from the European Training Network for the Design and Recycling of Rare-Earth Permanent Magnet Motors and Generators in Hybrid and Full Electric Vehicles (DEMETER), grant agreement 674973.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant