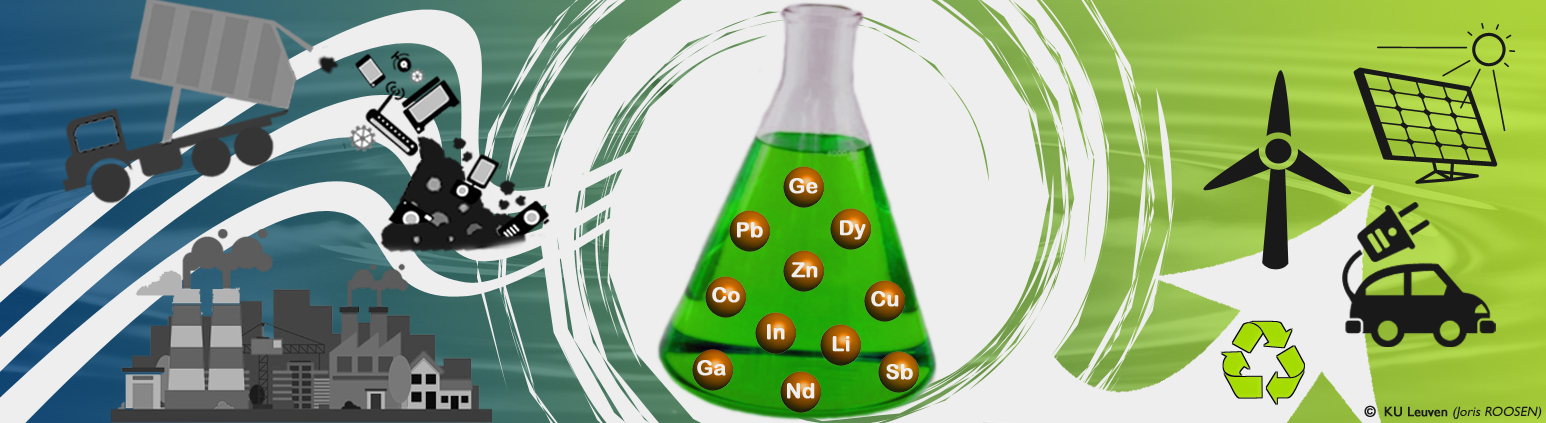

SIM² KU Leuven researchers have developed a new solvometallurgical extraction process to produce copper from sulphidic copper ore minerals such as chalcopyrite (see featured image). The innovation comprises a closed-loop process, using Ethylene glycol-FeCl3 as lixiviant. Metallic copper can be obtained by direct electrodeposition from the pregnant solution and, in the meantime, the oxidising agent FeCl3 can be regenerated. The work, which was performed with support from the EU Horizon 2020 ERC Advanced Grant SOLCRIMET project as well as the FWO, was published in the journal Green Chemistry. If industrially implemented, the process could allow to reduce the eco-footprint of primary copper production. The latter is key as copper is in high demand, given the ongoing electrification of mobility, which is, in its turn, an essential component in the transition to a climate-neutral economy.

Copper & electrification of mobility

The transition towards climate-neutral mobility requires the rapid electrification of this sector, combined with the use of electricity produced from renewable energy. To mass produce electric vehicles, there is an urgent need not only for exotic elements – such as lithium and cobalt (for the battery), as well as neodymium and dysprosium (for the e-motor) – but also for copper.

As the future copper requirements are much larger than what can be obtained through (even perfect) copper recycling from urban mines, there will be a need for the primary mining of copper.

Unfortunately, extraction of copper from sulphidic ores, either by pyrometallurgy or hydrometallurgy, is typically associated with a relatively large eco-footprint, in terms of energy requirements, CO2 emissions and/or the use of chemical reagents.

Reducing the environmental impact of primary copper production is, therefore, an important and timely research & innovation topic, to facilitate the transition to genuinely clean, climate-friendly mobility.

A new solvometallurgical process

In this new SIM² KU Leuven study, a solvometallurgical process for the extraction of copper from sulphidic ore minerals (chalcopyrite, bornite, chalcocite and digenite) was developed by using an organic lixiviant (FeCl3 as oxidising agent and ethylene glycol (EG) as organic solvent) (see Figure 1).

Figure 1. Schematic representation of the new process

Leaching

All the studied copper sulfide minerals could be leached efficiently with a FeCl3–EG solution. Other lixiviant systems, namely CuCl2–EG, FeCl3–ethanol and FeCl3–propylene glycol could also extract copper, but they did not perform as well as the FeCl3–EG combination. The leaching mechanism of chalcopyrite in FeCl3–EG solutions is:

CuFeS2 + 3 FeCl3 => 4 FeCl2 + CuCl 2 S

The fact that the oxidation product is elemental solid sulfur instead of sulphate ions (in the form of sulphuric acid) makes the process greener, because the sulfur can be easily collected, whereas the sulfuric acid needs to be neutralised with base before discarding to the waste water stream.

Copper recovery by electrodeposition

The metallic copper can be produced by direct electrodeposition from the pregnant leachate without any other competing electrochemical reactions (Figure 2). Meanwhile, Fe(III) can be regenerated for re-using in the next cycle by oxidising the Fe(II) in the anode.

Figure 2. SEM images of copper deposits obtained by applying ─0.30 V vs. Ag/AgCl for 2 hours at room temperature. The applied accelerating voltage equaled 20 kV.

The fast and efficient leaching, direct production of metallic copper and simultaneous regeneration the oxidising agent FeCl3, make up a sustainable, closed-loop solvometallurgical process, which could represent a key step forward towards lowering the eco-footprint of copper metallurgy.

Biography lead author

Xiaohua Li is a postdoctoral researcher working with Prof. Koen Binnemans at KU Leuven (SOLVOMET). She obtained her doctor degree from university of Twente in the Netherlands in February 2017 and started her work on SOLCRIMET project in KU Leuven from November 2016. In September 2019, she obtained a FWO postdoctoral grant to develop new ionic liquid-based aqueous biphasic system for rare-earth metal recovery. Her main research interests include separation technology, solvent extraction, leaching, metal recovery, solvometallurgy, aqueous biphasic system and ionic liquids.

Xiaohua Li is a postdoctoral researcher working with Prof. Koen Binnemans at KU Leuven (SOLVOMET). She obtained her doctor degree from university of Twente in the Netherlands in February 2017 and started her work on SOLCRIMET project in KU Leuven from November 2016. In September 2019, she obtained a FWO postdoctoral grant to develop new ionic liquid-based aqueous biphasic system for rare-earth metal recovery. Her main research interests include separation technology, solvent extraction, leaching, metal recovery, solvometallurgy, aqueous biphasic system and ionic liquids.

Full reference paper

Li, X.; Monnens, W.; Li, Z.; Fransaer, J.; Binnemans, K. Solvometallurgical process for extraction of copper from chalcopyrite and other sulfidic ore minerals, Green Chemistry, 2020, 22 (2), 417-426. https://doi.org/10.1039/C9GC02983D

Acknowledgements

The research leading to these results received funding from the European Research Council (ERC) under the European Union’s Horizon 2020 Research and Innovation Programme: Grant Agreement 694078 Solvometallurgy for critical metals (SOLCRIMET). The research was also funded by a PhD grant of the Research Foundation Flanders (FWO) to Wouter Monnens. (1SB8319N).

SIM² KU Leuven?

SIM² KU Leuven is the KU Leuven Institute for Sustainable Metals and Minerals (SIM² in short). SIM² is one of the four official KU Leuven Institutes that were endorsed by the KU Leuven Academic Council in November 2019. SIM² has more than 220 members, coming from a wide range of (interdisciplinary) research groups and departments at KU Leuven.

SIM²’s missions is “to develop, organise & implement problem-driven, science-deep research & future-oriented education, contributing to the environmentally friendly production & recycling of metals, minerals & engineered materials, supporting (…) a climate-friendly, circular-economy”. Read more about the new KU Leuven Institute here.

Follow SIM² on LinkedIn: https://www.linkedin.com/company/18118889

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant