Within the European ITN EREAN project, researchers from Fraunhofer and TU Darmstadt studied the influence of Ce and La substitution in NdFeB magnets by fast solidification and hydrogen treatments. The results were published in two journals: Journal of Magnetism and Magnetic Materials and Journal of Alloys and Compounds.

Along with recycling and grain boundary diffusion technologies (optimized, targeted dispensing of expensive performance enhancing rare-earth (RE) additives), the use of cerium and lanthanum, cost-saving and resource-efficient substitutes for Nd in Nd2Fe14B-based permanent magnets, has been a major focus in research since 2012. The aim is to alleviate production costs and ensure long term sustainability particularly for electric vehicle and wind energy industries which rely heavily on rare-earth permanent magnets. In a collaborative effort at Fraunhofer IWKS Hanau and the Functional Materials Group from TU Darmstadt, Iuliana Poenaru and colleagues studied the influence of Ce and La substitution on the structure and magnetic properties of Nd2Fe14B-based alloys processed by fast solidification and hydrogen treatments. The main results of this work are published in two articles in Journal of Magnetism and Magnetic Materials and Journal of Alloys and Compounds.

Ce and La substitution in Nd2Fe14B-based rapidly solidified and hydrogen treated alloys

Cerium or lanthanum replacement for Nd lowers the intrinsic magnetic properties of the Nd2Fe14B compound, setting a lower limit to the maximum achievable, theoretical performances comparing to the Nd-based compound. In practical alloys, depending on concentration and solidification conditions, substitution with Ce or La brings about changes in the phase constitution and the microstructure. Phase segregations such as CeFe2 and α-Fe occurring in Ce and respectively La substituted Nd2Fe14B alloys reduce magnetization as the relative fraction of RE2Fe14B hard magnetic phase is decreased and also reduce coercivity as they alter the grain structure and the composition and distribution of the intergranular phase.

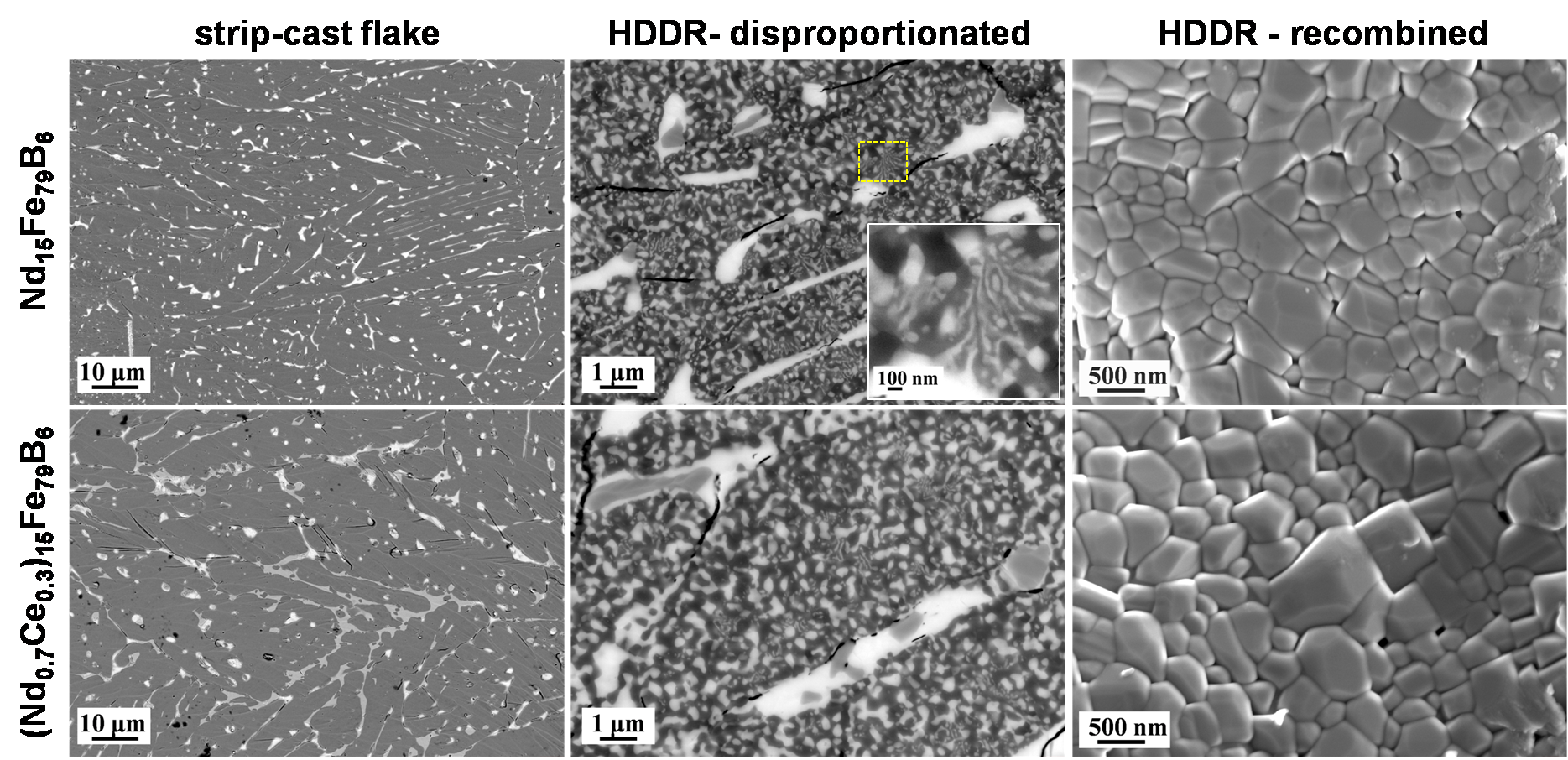

Fast solidification methods like melt-spinning and strip-casting were employed as effective approach to restrict segregations and refine the microstructure to minimize these effects. The structure and the magnetic properties of melt-spun alloys following the composition (Nd1-xREx)13.6FebalCo6.6Ga0.6B5.6 with RE = Ce, La were investigated. Further processing into anisotropic hot-deformed magnets confirmed that Ce improves deformability allowing for higher texture and magnetization to be attained. Strip-cast alloys of composition (Nd1-xCex)15Fe79B6 were exposed to hydrogen decrepitation (HD) followed by hydrogenation – disproportionation – desorption – recombination (HDDR) treatment. Results suggest that the hydrogenation and the subsequent thermal decomposition of CeFe2 phase allow its redistribution during the HDDR treatment which enables coercivity development in the HDDR powders with high Ce concentrations. Furthermore, HDDR proves to be a powerful probing method providing useful information relevant also for the powder sintering of Ce2Fe14B-based alloys.

Full reference papers

Poenaru, I., Lixandru, A., Gueth, K., Malfliet, A., Yoon, S., Škulj, I., and Gutfleisch, O., HDDR treatment of Ce-substituted Nd2Fe14B-based permanent magnet alloys – phase structure evolutions, intergranular processes and magnetic property development, Journal of Alloys and Compounds 814 (2020). https://doi.org/10.1016/j.jallcom.2019.152215

Poenaru, I., Lixandru, A., Riegg, S., Fayyazi, B., Taubel, A., Gueth, K., Gauss, R., and Gutfleisch, O., Ce and La as substitutes for Nd in Nd2Fe14B-based melt-spun alloys and hot-deformed magnets: a comparison of structural and magnetic properties, Journal of Magnetism and Magnetic Materials 478 (2019). https://doi.org/10.1016/j.jmmm.2019.01.095

Acknowledgement

The research leading to these results has received funding from the European Community’s Seventh Framework Programme ([FP7/2007-2013]) under grant agreement no. 607411 (MC-ITN EREAN: European Rare Earth Magnet Recycling Network). See previous Policy Briefs EREAN here.

SOLCRIMET Advanced ERC Grant

SOLCRIMET Advanced ERC Grant